Lesson AI Summary

In the augmented and virtual reality experience "Gauge Repeatability and Reproducibility in Compute," participants will explore the critical concepts of calibration, quality control, and measurement system analysis. Users will learn how calibration aligns measurement devices with known standards, ensuring accurate and comparable results across computer vision systems. The experience highlights the importance of Gauge Repeatability and Reproducibility (GR&R) in identifying sources of variation, emphasizing how different operators and devices can influence measurement outcomes. Participants will engage with statistical analysis tools like variance components and control charts to understand how to quantify and address variability. By tracing measurements back to their sources and logging data systematically, users will discover the importance of maintaining trust in automated decision-making systems. The interactive nature of the experience will allow users to simulate real-world scenarios, optimizing the interaction between operators and devices to achieve high reproducibility. Ultimately, this experience equips participants with the knowledge to improve measurement system performance, leading to better quality control and reliable data across various industries.

**Gauge Repeatability and Reproducibility in Computation**

Gauge Repeatability and Reproducibility (Gage R&R) are critical concepts in the realm of measurement systems analysis, particularly within manufacturing and engineering contexts. These concepts help organizations assess the precision and accuracy of their measurement systems, ensuring that data collected during production processes is reliable and valid. In computational fields, where data-driven decisions are paramount, understanding and implementing Gage R&R can lead to improved quality control and enhanced operational efficiency.

Gauge repeatability refers to the variation in measurements taken by the same instrument or operator under identical conditions (Montgomery, 2013). This aspect of Gage R&R focuses on the consistency of measurements when the same gauge is used repeatedly to measure the same item. For instance, in a computational setting where algorithms are designed to analyze data sets, repeatability ensures that the outputs remain stable when the same input data is processed multiple times. Lack of repeatability can indicate issues with the measurement system, such as instrument calibration, which can lead to erroneous conclusions and decision-making based on faulty data.

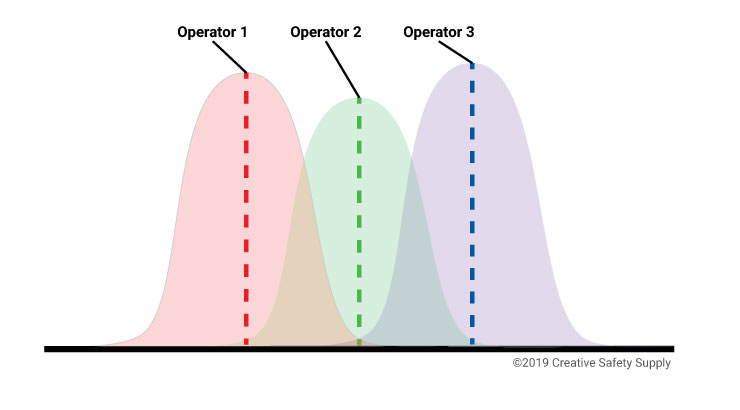

Reproducibility, on the other hand, pertains to the variation in measurements when different operators or instruments are employed to measure the same item (Montgomery, 2013). This aspect is particularly relevant in collaborative environments where multiple teams may be working on similar projects using different software or hardware tools. For example, if one team uses a specific computational model to analyze a data set and another team uses a different model, the ability to reproduce consistent results across both teams is vital for validating findings and maintaining the integrity of the overall analysis. Discrepancies in reproducibility can signal a need for standardization in measurement techniques or greater training for operators.

The implications of Gage R&R extend beyond mere measurement concerns; they play a crucial role in the broader context of quality management systems. As organizations strive for continuous improvement, understanding the factors contributing to variability in measurement systems is essential. By systematically analyzing Gage R&R, organizations can identify sources of error, implement corrective actions, and ultimately enhance product quality (Keller, 2019). Moreover, in today's data-centric world, the integrity of computational results hinges on the robustness of the underlying measurement systems.

In conclusion, Gauge Repeatability and Reproducibility are foundational concepts in ensuring the reliability and validity of measurements in computational fields. By focusing on both repeatability and reproducibility, organizations can foster an environment of quality and precision, leading to better data-driven decisions. As the complexity of data analysis continues to grow, the importance of Gage R&R will undoubtedly remain a critical aspect of quality assurance in computational practices.

### References

Keller, M. (2019). *Quality management for organizations: Principles and practices*. New York, NY: Routledge.

Montgomery, D. C. (2013). *Introduction to statistical quality control* (7th ed.). Hoboken, NJ: John Wiley & Sons.

### Lesson Plan: Understanding Gauge Repeatability and Reproducibility (Gage R&R)

#### Subject: Quality Control in Technical Vocational Studies

#### Duration: 90 minutes

#### Target Audience: Technical Vocational Students

#### Learning Objectives:

1. Understand the concepts of Gauge Repeatability and Reproducibility (Gage R&R).

2. Recognize how Gage R&R contributes to quality control in various technical fields.

3. Learn how to properly conduct Gage R&R studies.

4. Identify methods for maintaining and improving measurement systems.

---

### Lesson Outline

**I. Introduction (15 minutes)**

- **A. Hook/Engagement Activity:**

- Present a short video or animation illustrating the importance of precision in technical work (e.g., automotive or manufacturing).

- Ask students why precision matters and what could go wrong without it.

- **B. Overview of Gage R&R:**

- Define Gage R&R.

- Explain its importance in measurement systems and quality control.

**II. Concept Explanation (20 minutes)**

- **A. Definitions:**

- **Gauge Repeatability:** Variation in measurements taken by the same operator using the same measurement device under the same conditions.

- **Gauge Reproducibility:** Variation in measurements taken by different operators using the same measurement device under the same conditions.

- **B. Factors Affecting Gage R&R:**

- Equipment variation

- Operator variation

- Environmental conditions

- Measurement method

**III. Practical Application (30 minutes)**

- **A. Conducting a Gage R&R Study:**

- Divide students into small groups.

- Provide each group with a measuring device and a consistent set of parts to measure.

- Assign different operators within the group to take measurements.

- Each operator measures the same part multiple times.

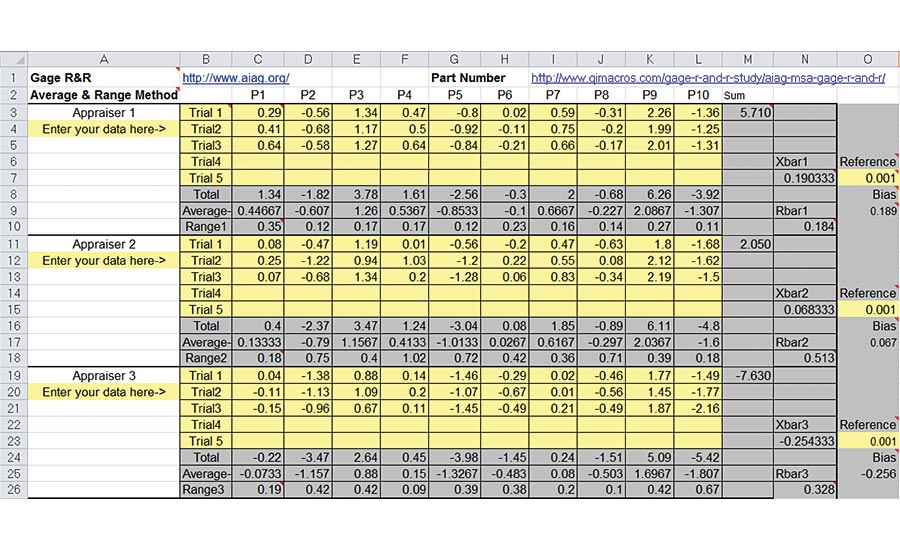

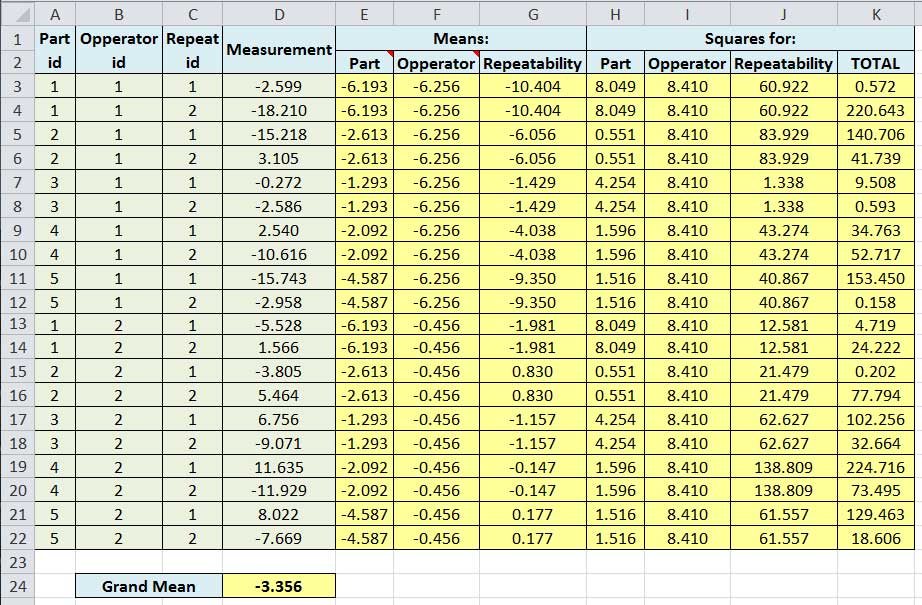

- **B. Data Analysis:**

- Introduce students to basic statistical tools to analyze the collected data (mean, standard deviation).

- Guide students through calculating Repeatability and Reproducibility.

- Discuss the implications of their findings (e.g., acceptable quality levels, potential issues).

**IV. Maintenance of Measurement Systems (15 minutes)**

- **A. Best Practices for Maintaining Measurement Systems:**

- Calibration: Importance and frequency.

- Routine checks and maintenance schedules.

- Training of operators to ensure consistency.

- **B. Continuous Improvement:**

- Discuss techniques for identifying and minimizing variability in measurement (e.g., Six Sigma principles).

**V. Wrap-Up and Q&A (10 minutes)**

- Summarize key points.

- Open the floor for questions.

- Provide additional resources for further reading (articles, websites, videos).

### Assessment

- **Formative Assessment:**

- Observe group activity participation and understanding during the practical application.

- **Summative Assessment:**

- Quiz at the end of the lesson covering key definitions, concepts, and practical applications of Gage R&R.

### Materials Needed

- Measuring devices (calipers, micrometers, etc.)

- Consistent set of parts to measure (e.g., blocks, rods)

- Statistical software or calculator for data analysis

- Whiteboard and markers for group discussions

- Handouts summarizing key concepts and formulas

### Additional Notes

- Adapt the lesson depending on the students' prior knowledge and the specific technical field they are studying.

- Ensure that all measurement devices are calibrated and in good working condition prior to the lesson.

- Encourage students to relate Gage R&R to real-world scenarios they may encounter in their future careers.

# Syllabus for Gauge Repeatability and Reproducibility in Computing

## Course Overview

This course provides an in-depth understanding of Gauge Repeatability and Reproducibility (Gage R&R) within the context of computing systems. Students will learn the principles, methodologies, and applications of Gage R&R to ensure consistent and accurate measurement systems in various computing environments.

### Course Objectives

By the end of this course, students will be able to:

1. Define and explain the concepts of Gauge Repeatability and Reproducibility.

2. Analyze and evaluate measurement systems in computing.

3. Apply statistical tools to assess Gage R&R.

4. Conduct Gage R&R studies and interpret results.

5. Implement strategies to improve measurement systems based on Gage R&R findings.

## Course Format

- **Duration:** 12 weeks

- **Classes:** 2 sessions per week, 90 minutes each

- **Delivery Mode:** Hybrid (in-person and online)

- **Assessments:** Quizzes, Projects, Midterm, Final Exam

## Weekly Breakdown

### Week 1: Introduction to Measurement Systems

- **Topics:**

- Overview of measurement systems in computing

- Importance of accuracy and consistency

- **Readings:**

- Chapter 1 of "Measurement System Analysis"

- **Activity:** Group discussion on measurement challenges in computing.

### Week 2: Fundamentals of Gage R&R

- **Topics:**

- Definition of Gage R&R

- Components of measurement variation

- **Readings:**

- Chapter 2 of "Measurement System Analysis"

- **Activity:** Case study review.

### Week 3: Types of Variation

- **Topics:**

- Common types of variation (repeatability, reproducibility)

- Factors affecting measurement systems

- **Readings:**

- Articles on sources of measurement error

- **Assessment:** Quiz 1.

### Week 4: Statistical Foundations

- **Topics:**

- Basic statistics for Gage R&R (mean, variance, standard deviation)

- Introduction to normal distribution

- **Readings:**

- Chapter 3 of "Statistics for Engineers"

- **Activity:** Hands-on statistical exercises.

### Week 5: Designing a Gage R&R Study

- **Topics:**

- Planning and designing a Gage R&R study

- Selecting measurement instruments and operators

- **Readings:**

- Guidelines for conducting Gage R&R studies

- **Activity:** Group project planning.

### Week 6: Data Collection and Analysis

- **Topics:**

- Methods for collecting data in Gage R&R studies

- Analyzing data using statistical software

- **Readings:**

- Software tutorials and data analysis guides

- **Assessment:** Project submission (Study Design).

### Week 7: Interpreting Gage R&R Results

- **Topics:**

- Understanding Gage R&R results and metrics

- Identifying sources of variation

- **Readings:**

- Case studies on Gage R&R results interpretation

- **Activity:** Interactive analysis of sample data.

### Week 8: Midterm Exam

- **Topics:**

- Comprehensive review of Weeks 1-7

- **Assessment:** Midterm Exam.

### Week 9: Improving Measurement Systems

- **Topics:**

- Strategies for reducing variation

- Continuous improvement methodologies (Six Sigma)

- **Readings:**

- Articles on quality improvement techniques

- **Activity:** Workshop on implementing changes.

### Week 10: Advanced Gage R&R Techniques

- **Topics:**

- Advanced statistical methods in Gage R&R

- Multi-variable studies

- **Readings:**

- Advanced chapters from "Measurement System Analysis"

- **Assessment:** Quiz 2.

### Week 11: Real-World Applications of Gage R&R

- **Topics:**

- Case studies from industry (software development, hardware testing)

- Discussion on the impact of Gage R&R on product quality

- **Readings:**

- Industry reports on Gage R&R applications

- **Activity:** Group presentations.

### Week 12: Course Review and Final Exam

- **Topics:**

- Review of key concepts and methodologies

- Future trends in measurement systems

- **Assessment:** Final Exam.

## Grading Breakdown

- Quizzes: 20%

- Project: 30%

- Midterm Exam: 25%

- Final Exam: 25%

## Required Materials

- **Textbooks:**

- “Measurement System Analysis” by (Author)

- “Statistics for Engineers” by (Author)

- **Software:**

- Statistical analysis software (e.g., Minitab, R, Python)

## Instructor Information

- **Name:** [Instructor Name]

- **Email:** [Instructor Email]

- **Office Hours:** [Days and Times]

---

### Additional Notes

- Participation in class discussions and activities is essential for success in this course.

- Students are encouraged to collaborate on projects but must ensure that all submitted work is original.

- Accommodations are available for students with disabilities; please contact the instructor for arrangements.

Welcome to the course! Let’s explore the critical role of measurement systems in computing together!

### Learning Objectives for a Course on Gauge Repeatability and Reproducibility in Compute

1. **Understand Fundamental Concepts**

- Define and explain the principles of Gauge Repeatability and Reproducibility (GR&R) in the context of measurement systems.

- Identify the importance of GR&R in ensuring quality and accuracy in technical applications.

2. **Identify Measurement Systems**

- Recognize different types of measurement systems and gauges used in various technical fields.

- Distinguish between qualitative and quantitative measurements in relation to GR&R.

3. **Analyze Sources of Variation**

- Analyze factors that contribute to measurement variation, including operator, equipment, and environmental influences.

- Evaluate how each factor impacts the overall reliability and validity of measurement results.

4. **Conduct GR&R Studies**

- Design and implement a GR&R study using appropriate statistical methods to assess measurement systems.

- Collect and analyze data to calculate key GR&R metrics, including repeatability, reproducibility, and total variation.

5. **Interpret GR&R Results**

- Interpret the results of GR&R studies to determine the adequacy of measurement systems.

- Make informed recommendations for improving measurement processes based on GR&R findings.

6. **Apply Statistical Tools**

- Utilize statistical software and tools to perform GR&R analyses and visualize data effectively.

- Understand and apply concepts such as variance components analysis and control charts in the context of GR&R.

7. **Implement Continuous Improvement Practices**

- Develop a plan for continuous improvement based on GR&R results to enhance measurement system performance.

- Foster a culture of quality and precision in measurement practices within technical environments.

8. **Communicate Findings Effectively**

- Prepare and present clear reports that summarize GR&R study findings, conclusions, and recommendations for stakeholders.

- Develop effective communication skills to articulate the significance of GR&R in ensuring measurement integrity.

By the end of this course, students will have a comprehensive understanding of Gauge Repeatability and Reproducibility, equipping them with the skills to implement and analyze measurement systems effectively in their technical careers.

Sure! Here are five multiple choice questions focused on Gauge Repeatability and Reproducibility (Gage R&R) in a computing context, along with the correct answers.

### Question 1:

What does Gauge Repeatability and Reproducibility (Gage R&R) primarily assess in a measurement system?

A) The speed of data processing

B) The consistency of measurements

C) The complexity of algorithms

D) The cost of measurement tools

**Answer:** B) The consistency of measurements

---

### Question 2:

In the context of Gage R&R, what is "repeatability"?

A) The ability of different operators to produce the same measurement

B) The ability of the same operator to obtain the same measurement under the same conditions

C) The variation caused by different measurement instruments

D) The overall accuracy of the measurement system

**Answer:** B) The ability of the same operator to obtain the same measurement under the same conditions

---

### Question 3:

Which of the following factors is NOT typically considered when conducting a Gage R&R study?

A) Measurement equipment calibration

B) Environmental conditions during measurement

C) The operator's level of experience

D) The aesthetic design of the measurement tool

**Answer:** D) The aesthetic design of the measurement tool

---

### Question 4:

What is the main purpose of conducting a Gage R&R study in a computing environment?

A) To analyze the speed of software applications

B) To improve user interface design

C) To ensure that the measurement system is reliable and valid for decision-making

D) To enhance data storage capabilities

**Answer:** C) To ensure that the measurement system is reliable and valid for decision-making

---

### Question 5:

When interpreting Gage R&R results, what is the acceptable percentage of total variation that is often cited as a benchmark for a measurement system to be considered adequate?

A) Less than 5%

B) Less than 10%

C) Less than 30%

D) Less than 50%

**Answer:** C) Less than 30%

---

Feel free to adjust the questions or answers as needed!

AI Conversation

Calibration

Calibration is the process of adjusting measurement devices to align with known standards. Regular calibration ensures that all devices provide accurate, comparable results. In computer vision systems, calibration minimizes systematic errors, supporting both repeatability and reproducibility by standardizing device performance.

https://www.youtube.com/watch?v=CkLEmiKFnTw

quality control

Quality control uses GR&R findings to maintain and improve measurement system performance. By identifying and addressing sources of variation, organizations can implement corrective actions, update procedures, and ensure consistent product or process quality. Quality control is essential for maintaining trust in automated decision-making systems.

data logging and traceability

Data logging involves systematically recording measurement results, operator identities, and device information. Traceability ensures each measurement can be linked back to its source. These practices are vital for analyzing measurement variation, identifying trends, and supporting corrective actions in quality control processes.

reproducibility

Reproducibility measures the variation in results when different operators or devices measure the same item under the same conditions. It highlights the influence of human or equipment differences on measurement outcomes. High reproducibility means results are consistent across users and devices, supporting system reliability.

https://www.youtube.com/watch?v=lyW7nH5kqSQ

statistical analysis

Statistical analysis in GR&R studies quantifies sources of variation using tools like variance components, control charts, and analysis of variance (ANOVA). These methods help determine whether observed differences are due to the measurement system or the items measured, guiding improvements in system reliability.

gauge repeatability and reproducibility in compute

Gauge Repeatability and Reproducibility (GR&R) is a measurement system analysis method that quantifies variation in measurement results due to the measurement process, including devices and operators. It is essential for ensuring consistent, reliable data in automated systems, supporting quality control and informed decision-making across various industries.

https://www.youtube.com/watch?v=NdlGhtn6KJE

measurement system analysis

Measurement System Analysis (MSA) evaluates the accuracy and precision of measurement processes. It identifies sources of variation, such as equipment, operators, and environment, ensuring that data collected is reliable. MSA is foundational for quality control and is the broader framework within which GR&R studies are conducted.

https://www.youtube.com/watch?v=PAJIKXZnmx4

human and machine interaction

The interaction between operators and measurement devices can introduce variability. Factors such as user technique, training, and device usability all impact measurement outcomes. Understanding and optimizing this interaction is crucial for achieving high reproducibility and ensuring the effectiveness of automated systems in real-world environments.

repeatability

Repeatability refers to the variation observed when the same operator uses the same device to measure the same item multiple times under identical conditions. High repeatability indicates the measurement system produces consistent results, while low repeatability suggests internal inconsistencies or instability in the device or process.

https://www.youtube.com/watch?v=aQligHSGvMA